vickers hardness test for polymers|vickers hardness test chart : advice The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or .

WEBRádio Bons Ventos, FM 107.3, Goiânia. Live stream plus station schedule and song playlist. Listen to your favorite radio stations at Streema.

{plog:ftitle_list}

Book Of Ra Deluxe, il successo di una Slot Machine. Book O.

ISO 2039-2 and ASTM D785 define various Rockwell hardness scales for plastics testing. In contrast to ball indention hardness, in which the indention depth is measured under load, with the Rockwell method, the indention depth . Abstract. Hardness is a useful measure of a material’s resistance to permanent indentation; but for viscoelastic polymers, hardness data are highly dependent on the test .Vickers hardness test is also known as the diamond pyramid hardness test which employs a diamond pyramid indenter and variable loads ranging from 1 to 120 kg. The Vickers hardness . Weiler tested micro-Vickers hardness on several thermoplastic polymers and obtained hardness values. Establishing a correlation between Vickers hardness and yield stress will enable the evaluation of thermoplastic .

Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation .

The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or .

Vickers microhardness testing is used to leave small indents (<150 µm) and is shown to be applicable to polymers. A detailed investigation of the required steps for .When you require precise measurements for materials with high hardness or thin coatings – the Vickers hardness test is suitable. When needing to perform hardness testing on-site or non-destructively – the Leeb hardness test .

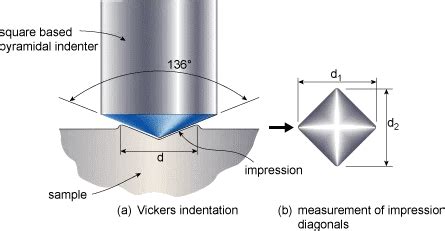

Micro Vickers hardness testing is commonly used as a method to quantify resistance to permanent plastic deformation of metals by using indentation of the surface. Due to the .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .Metals • Plastics • Rubbers • Polymers • Ceramics • Composites • Coatings. . The Vickers hardness test uses a square-based pyramid diamond indenter with an angle of 136° between the opposite faces at the vertex, which is pressed .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard .The Vickers hardness number (HV) is calculated based on the indentation diagonal lengths. This method is suitable for a wide range of materials, including metals, ceramics, and plastics. Due to its small indentation size the Vickers .A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area. EN ISO 6507-1 specifies he following are the three ranges of test force and their corresponding Vickers hardness test designations: F ≥ 49.03 N - Designation: HV 5 - Standard Vickers hardness test method for testing metals and materials with a medium to high hardness range. 1.961 ≤ F < 49.03 N - Designation: HV 0.2 to

Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. While it can be used to test the hardness of metals and other hard materials, its main focus is on [.] Macrohardness Testing: While primarily a microhardness test, Vickers hardness testing can also be adapted for macrohardness testing of larger samples. General Purpose Testing: Vickers hardness testing is versatile and well-suited for general-purpose hardness testing across various industries and applications. When to Use Knoop Hardness Testing

Hardness testing has proved to be very popular in many fields because of its relative simplicity and non-destructive nature and it has been particularly successful in quality control situations where it can be used as an indication of surface durability and, in some cases, as an indication of strength. 37 Polymer Testing 0142-9418/82/0003-0037 .

Some materials (e.g. metals, ceramics) are harder than others (e.g. plastics, wood). Hardness is an important parameter correlating with . Another advantage of the Vickers hardness test is absence of different scales, as compared to Rockwell and Brinnell tests. At low values (VH<~400HV), Vickers hardness was shown to be the same as Brinell .

Rockwell hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Rockwell E, M, and R scales of hardness are commonly used for 'hard' polymers such as nylon, polystyrene, acetal, and polycarbonate. . Other hardness topics in Mat: Vickers Hardness Testing - Microhardness; Shore .The easy to use hardness testing software supports the operator with single tests, as well as complex test tasks. Hardness testing according to current standards. Our DuraVision series offers a wide load range from 0.3-250 kg or from 3-3,000 kg for test methods including Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing.

charpy impact test instron

Hardness is a useful measure of a material’s resistance to permanent indentation; but for viscoelastic polymers, hardness data are highly dependent on the test type and the parameter set chosen.Learn how Shore D Hardness test work, its significance to determine hardness of the material as well as what are common polymers this test is used for. . For rubbers, elastomers & softer plastics, Shore Hardness is often preferred. Very soft materials can be measured using Shore A hardness. It is generally used for hard materials, like PA, PC

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).Vickers hardness test is a standard method for measuring materials' hardness, which is commonly used to measure the hardness or softness of substances like metals, minerals, and plastics. Here's the article for you to everything about Vickers hardness testing, including basics and principle, Vickers hardness test procedure, formula and calculation. 1. Vickers microhardness testing For microhardness testing according to Vickers, the indenter is a diamond in the form of a square-based pyramid with an angle of 136 degrees. This square shape makes the Vickers .A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, . For some metals and polymers, there are empirical correlations between hardness and strength (or modulus) of the material. In microhardness testing, a diamond indenter of a specific geometry (e.g .

Applications of Vickers Hardness Testing: Material Characterization: Vickers hardness testing is commonly used to determine the hardness of various materials, including metals, ceramics, and polymers.This information is crucial for understanding material properties, such as wear resistance, toughness, and strength. One can apply a force slowly along the main axis of the specimen—such as in tensile testing. One can apply a force rapidly perpendicularly to the surface—such as in Vickers hardness determination. We provide for polymers an equation relating their tensile elongation at break to the Vickers hardness.Shore hardness test, for polymers, widely used in the rubber industry. [10] . Microindentation hardness testing can be done using Vickers as well as Knoop indenters. For the Vickers test, both the diagonals are measured and the average value is .

PRACTICAL HARDNESS TESTING MADE SIMPLE Table of Contents Page 1. GENERAL 1 2. INTRODUCTION 3 3. BRINELL HARDNESS TESTING 9 4. VICKERS HARDNESS TESTING 14 5. ROCKWELL HARDNESS TESTING 17 6. INFORMATIONS 22 i PRACTICAL HARDNESS TESTING MADE SIMPLE 1. GENERAL Important facts and features to be known and .

vickers hardness testing procedure

Vickers Hardness Testing. Microhardness testing of metals, ceramics, and composites is useful for a variety of applications for which 'macro' hardness measurements are unsuitable: testing very thin materials like foils, measuring individual microstructures within a larger matrix, or measuring the hardness gradients of a part along the cross section.The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. .What standard test methods measure hardness of plastics? ISO 2039-1:2001 — It determines the hardness of plastics. It uses the ball indentation method. ISO 2039-2:1987 — It determines the hardness of plastics. It uses the Rockwell hardness scale.

charpy impact test interpretation

Shore Durometer hardness testing of plastics is described, and conversion charts correlating various scales are presented. The Shore Duromter A and D scales of hardness are commonly used for rubber and 'soft' polymers such as polyolefins, polyurethanes, vinyl, and fluoropolymers. . Vickers Hardness Testing - Microhardness; Rockwell Hardness .

Although this table only represents metal hardness testing, polymers and elastomers can also be tested using slightly different testing methods (e.g. Shore hardness). . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially .In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

charpy impact test iso 179

charpy impact test iso 179 astm d6110

charpy impact test journal

WEB19 de fev. de 2024 · Read Review. All Slots Casino 3.5 /5 Mobile Play. 100% Match Bonus Up to $1500. Read Review. Mars Casino 3 /5 Mobile Play. 100% Match Bonus Up to $400. Read Review. At more than a quarter of a century old Ainsworth (or Ainsworth Game Technology to use the full name) has plenty of experience. It was founded by Australian .

vickers hardness test for polymers|vickers hardness test chart